Flexible packaging systems have undergone profound changes with the introduction of various automation technologies. For instance, polybag machines, especially the sup pouch machines, have become integral in the realization of flexible and durable packaging solutions. The automation of packaging systems has been on the rise due to the increasing need for high quality, low cost, and high-quality customizable packaging. This paper investigates the impact of automation on flexible packaging, and more specifically, the impact of polythene bag making machines on production process streamlining for companies in various industries.

The Growth of Automated Polybag Machines in Flexible Packaging

Flexible packaging has witnessed a shift to automation in the recent past. Polybag machines, for example, stand up pouch making machines, have changed the modal approach to packaging production by businesses. In this era of advanced technologies, the use of these automated systems helps in increasing the efficiency of production systems by saving on time, precision, and cost of packaging produced.

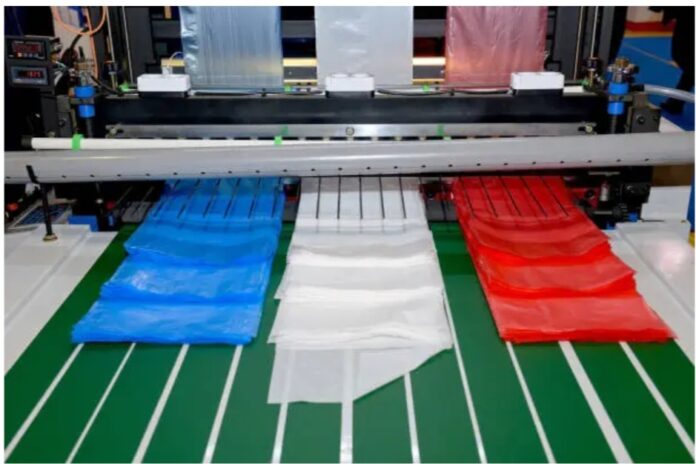

With respect to flexible packing, polybag machines provide versatility with all of the various bag types, including, but not limited to, flat and stand-up pouches used in food and beverage packaging, pharmaceuticals, and consumer goods. Businesses wishing to achieve efficiency while augmenting manual labor and product consistency have all shifted polybag machines to the ever-growing market trend.

Key Benefits of Automated Polybag Machines

Increased production speed. Stand-up pouch machines, do as their namesakes suggest and manufacture stand-up pouches – and do so in a fraction of the time any person could. Why should a business sacrifice quality for efficiency when both can be attained simultaneously?

Automation and Artificial Intelligence have never been more useful. Machines that produce polybags do so with impeccable consistency. Each bag is produced to the exact size and shape of the last, which virtually eliminates any junk produced in the manufacturing process. Error and Wastage. Sounds nice together, huh?

The more personnel a business has, the more time is wasted as they allocate manpower to simple, easily automated, and process tasks. Focus should be diverted to more critical aspects of production that truly require a human touch and the business as a whole will enjoy the reduced overall expenditure.

- Improved Flexibility: Automated polybag machines give businesses the opportunity to design unique customer-centric packaging solutions. This can include value adding features such as reclosable zippers, spouts, or even windows.

Stand-Up Pouch Making Machines: Revolution in Packaging

In the last few years, the use of stand-up pouches has increased tremendously due to their functional design and aesthetic appeal. Compared to other packaging alternatives, stand-up pouches pop out for their market visibility and sellability, customer convenience, as well as their ability to hold different types of products in a compact, lightweight packaging.

Stand-up pouch making machines sit at the center of the new trend, enabling producers to manufacture pouches with a high degree of customization and durability. These machines streamline the production of stand-up pouches by automating film unwinding, pouch sealing, and cutting, leading to increased production speed, quality control, and reduced labor costs.

Stand-up pouch making machines have benefited from the added advantage of innovative automation technology, allowing businesses that adopt them to gain a competitive advantage in the industry by offering a wider range of packaging solutions.

Advantages of Stand-Up Pouches in Flexible Packaging

Stand-up pouches provide certain advantages compared to other types of flexible bags. This is why they are widely used in many industries:

- Space Utilization: Stand-up pouches save shelf space compared to rigid pack types. This is useful in places like supermarkets, convenience stores, and pharmacies where space is often at a premium.

- Enhanced Product Appeal: Stand-up pouches’ clear front panels look more appealing at point of sale and can help in improving sales.

- Light and Easy to Carry: Stand-up pouches are lightweight and easy to pack. This is an important feature especially for consumers and businesses in industries that do high volume shipping.

- Lower Price: Stand up pouches are more economical as compared to rigid traditional packaging especially when considering all costs of pack storage, shipping, and materials.

Importance of Polybag Machines to Meet Ever-increasing Packaging Requirements

With more and more companies looking for faster and more versatile packaging solutions, polybag machines with certain automation features are the answer. With industries such as food and beverage, cosmetics, and pharmaceuticals looking for versatile, flexible and faster options, polybag machines deliver the needed speed and flexibility.

The addition of features like digital printing, multi-layered films, and reclosable zippers have increased the sophistication of self-service and automated polybaggers machines. They have also enabled businesses to lower their costs and better respond to the evolving demands of the market by providing precision flexible packaging.

Using automated polybag machines on self-service stands to increase foldable polybag tiered pack sustainability

Automated polybag machines also have the added benefit of lowering operational costs by improving the efficiency of the entire polybagging and packaging line. Most newer models of automated polybag machines can pack boxes and tiers of boxes for shipment, eliminating the need for additional semi automated or manual machines to pack polybags into boxes. They can also serve the rising demand from businesses and consumers for lower impact packaging by using post consumer recyclable films and biodegradable polymers.

The use of self-service automated polybag machines allows manufacturers to meet the needs of eco-conscious consumers for polybagged foods by providing secure, easy to open, and resealable pouches of the food pouches. They also have the ability to retain the robustness and functionality of the polybag, which is important for consumers or businesses that need to use the pack for tough retail environments.

Important Factors to Consider When Choosing a Stand-Up Pouch Making Machine

When choosing a stand-up pouch making machine, there are a range of features that affect the machine configuration and performance to best serve the needs of the polybag business. Here are some examples to keep in mind that should assist businesses in selecting the right machine:

- Production Rate: Stand-up pouch making machines should be capable of high speed and high volume production to meet market demand and sustain production.

- Flexibility: Selected machines should be able to accept multiple pouch sizes and configurations to prepare for diverse packaging needs.

- Coating: The ability to produce laminated films, reinforced foil, and other clear plastic bags allows for stand-up pouch making machines to be made with differing materials to accommodate multiple products.

- Minimized Downtime: Identify machines that have minimal maintenance requirements as well as dependable after sales service to alleviate machine standby time.

- Balance between Manual and Automated Techniques: The machine should offer preset technical configuration for smooth film delivery, deft closure, and clearance to touch panel interface for end users to maintain optimum streamlining within the pack out flow.

The Future of Polybag Machines in Flexible Packaging

Automated polybag machines, and in particular stand-up pouch making machines, will only become more mainstream as the flexible packaging market continues to expand. New automation systems within the packaging industry will be developed to meet the growing need for flexible, eco-friendly, and customizable packaging.

In the future, businesses will witness advanced capabilities in machines in terms of energy usage, output, and customization. In a highly dynamic and competitive environment, with the help of these advanced machines, businesses will be able to provide high volume, agile, and quality packaging at competitive prices.

In conclusion, the compact automated polybag machines, and in particular the stand-up pouch making machines, have been a game changer in the flexible packaging industry. They have enabled businesses to satisfy the demand for competitively priced, high quality, and efficient packaging. These machines have become a standard for today’s businesses owing to the increased production rate and lower packaging prices.

The outlook for future polybag machines seems bright with the incorporation of emerging automated technologies which will allow businesses to diversify and gain a competitive edge. These advanced systems will enable improved operational efficiencies, lower costs, and increased pack added value for the products.