The modern challenges of healthcare and medical technologies have created a need for more flexible, sterilizable, and durable device housings. Every new medical device brings with it new requirements and complexities, both in terms of construction and engineering. The techniques and methods used to fabricate medical devices face increasingly more complex requirements regarding hygiene, care, and overall durability.

The driving force of this change is medical fabrication, which utilizes modern technology and meticulous manufacturing techniques to produce appropriate enclosures and components, which can withstand medical environments. Innovations in this area are being supported by leading medical fabrication companies, like precision sheet metal products inc, that focus on making metal fabrication more accurate, consistent, and flexible.

The Additional Important Factors of Medical Device Housings

Alongside the aesthetic and protective purposes, the housings have to adhere to strict compliance and regulatory requirements, undergo repeated sterilization cycles, and seamlessly integrate with electronics and other system components. Any error in device housings construction could severely undermine the functional capabilities of the device and the safety of the patient.

Plastic enclosures are unsuitable for high-temperature sterilization or prolonged chemical exposure. Here, medical fabrication as applied to sheet metal is beneficial. Metal housings are more durable, can be shaped to precise specifications, and can be treated or coated with antimicrobials for cleanliness compliance.

In addition, the wearable monitors and handheld diagnostic equipment and tools that are increasingly in demand need to be portable and intricately designed and thus, compact. Fabricators like Precision Sheet Metal Products, Inc. facilitate this with tight-tolerance metal parts designed to be strong yet miniaturized.

Materials Matter: Choosing the Right Metals for Medical Enclosures

The right metal choice is important for achieving the optimal combination of strength, weight, corrosion resistance, and the ability to be sterilized. In medical fabrication, the following materials are common:

- Stainless Steel (304 & 316L): has strong corrosion resistance and mechanical strength, as well as the ability to be autoclaved or chemically sterilized.

- Aluminum Alloys: has strong lightweight properties and is thermally conductive. It is anodized for hygiene and increased durability.

- Titanium: has the strongest biocompatibility and corrosion resistance. Is highly sought after for high-end or implantable devices.

- Copper and Copper Alloys: Antimicrobials by nature and thus, are only used for select components.

Aside from the functionality, the methods of fabrication and surface finishing play a crucial role too. That’s why businesses like Precision Sheet Metal Products Inc focus on compliance and performance, offering specialized services in material selection to ensure deep expertise in compliance and performance.

High Precision, Compact Design: Technology Meets Contemporary Needs

GPS tracking devices and miniaturization of medical devices add a fresh layer of sophistication in the industry. These components ought to be robust and hygienic while accurately formed to micrometer tolerances for effortless integration in tightly constrained spaces.

The last few decades have witnessed a surge in modern techniques:

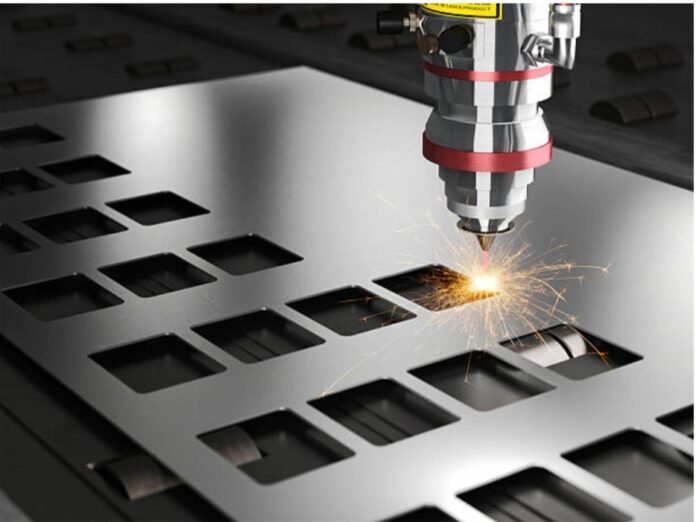

- Laser Cutting: Defined to be high speed and burr-free, yielding robust and hygiene-adhering edges critical for tight-tolerance assemblies.

- CNC Bending & Forming: Addresses uniformity across complex and smaller batches.

- Micro-Welding: Perfecting sharp and gentle connection on sensitive materials enables clean and strong joints.

- Surface Finishing: This focuses on electropolishing, passivation and coating of other surfaces to enhance cleanliness.

Leading specialists in the industry, including Precision Sheet Metal Products Inc, are equipped with the right surface finishing techniques to manufacture custom or small-batch enclosures with eagerness to compliance and functionality. Every element, whether a compact surgical tool housing or a portable ECG unit, undergoes rigorous testing to be tailored to exacting standards.

Ensuring Sterilizability and Regulatory Compliance

A device’s medical applicability relies on the device Sterilizability which is isolable to the medical device housings. Enclosures should resist degradation due to heat and pressure exposure, chemicals, and radiation. In addition, the design should not have gaps and irregular surfaces which could harbor contaminants.

Medical fabrication for these applications requires strict adherence to standards such as:

- ISO 13485: Qualifying management for medical device manufacturing.

- FDA 21 CFR Part 820: Good Manufacturing Practice (GMP) regulations.

- RoHS and REACH: Ensuring the safe use of materials and environmental compliance.

Cleanroom manufacturing, thorough documentation, and comprehensive traceability form the essential parts of the framework. Inc. precision sheet metal products have long provided such services. Their thorough knowledge of these regulations facilitates seamless incorporation of compliance into all design and production phases.

Future Trends in Medical Metal Fabrication

The future of medical fabrication will focus on digital and precision. The more medical devices containing sensors, AI, and connectivity features, the more advanced the enclosures will need to become.

Emerging trends include:

- Smart Enclosures: Housings which include sensors, antennas, and other interfaces for data transmission.

- Additive Manufacturing Integration: Metal parts designed to be hybrid with separately 3D printed plastic parts.

- Sustainable Fabrication: Achieving environmental objectives through the use of recyclable metals and environmentally friendly techniques.

- Design for Disassembly: Enhancements that allow for easier servicing, sterilization, or end-of-life recycling of components.

As these developments emerge, precision sheet metal products inc and other advanced fabricators are poised to help B2B medical technology companies even more with adaptive, scalable, and high-quality fabrication.

One integrated sentence with both keywords: Innovative precision sheet metal products inc continue to evolve with medical device innovation and are essential as adaptive partners for compact, dependable, and sterilizable housings to meet contemporary healthcare needs.

Conclusion

Device housing innovation is critical in the medical field where every millimeter counts and safety is a priority. Medical fabrication now needs more than structural strength; it needs contour, ultra-clean, and high-tech precision.

Precision sheet metal products inc and other specialized fabricators are answering the call alongside B2B suppliers as the demands for quality, hygiene, and design flexibility escalate. These fabrication solutions from compact housings for diagnostic tools to robust frames for surgical equipment form the backbone of next-generation healthcare technology.

With trusted fabrication partners, medical device developers can assure complete compliance along with accelerating time to market, resulting in dependable devices for both doctors and patients.